Thermal Conductivity Of Hardwood Siding

The wood dries rapidly and does not easily warp cup end check splinter or split.

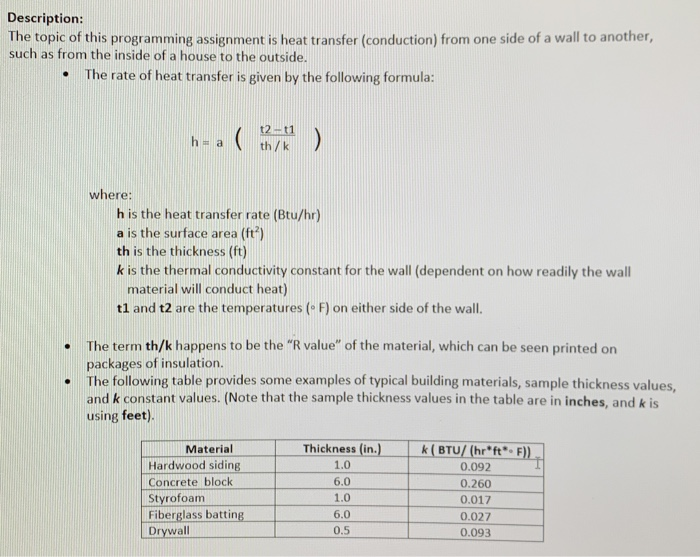

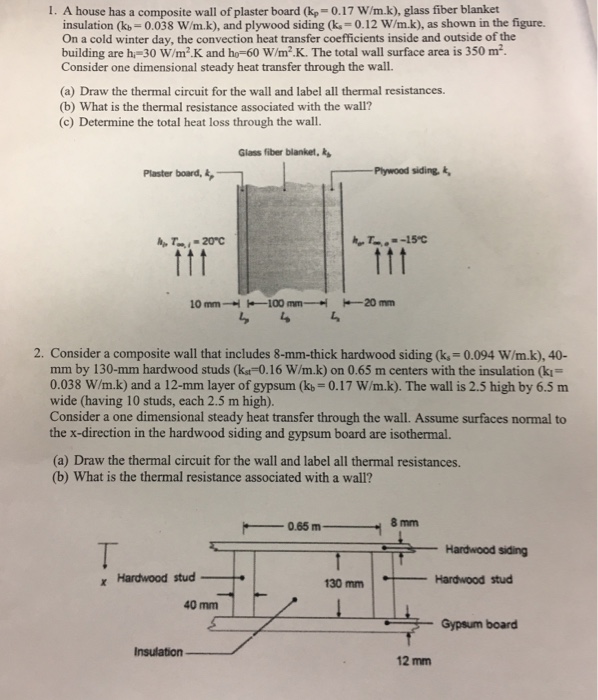

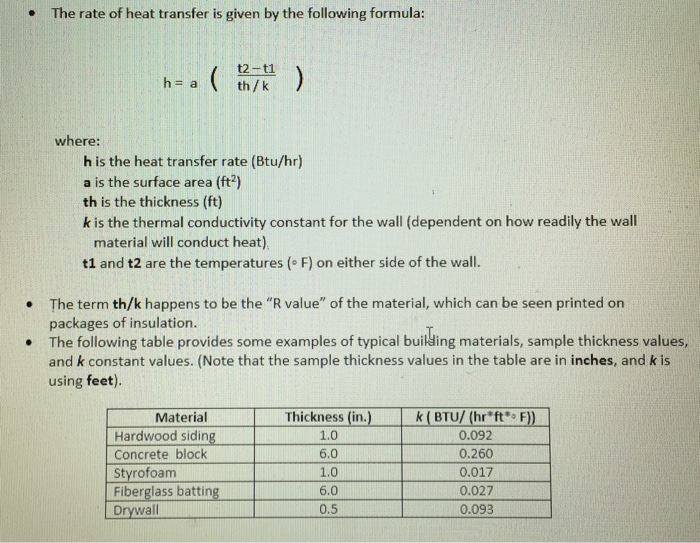

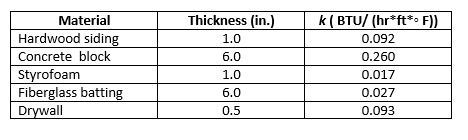

Thermal conductivity of hardwood siding. Hour degf. Thermal conductivity values of any wood. In construction the r value is the measurement of a material s capacity to resist heat flow from one side to the other. Presently wood has become an alternative to brick in the construction of homes.

K btu inch sq ft. The average coefficient of linear thermal expansion is about 3 4 x 10 6 inch inch per degree f for a plywood panel with 60 percent of the plies or less running perpendicular to the face. C or thermal conductance of these materials is the reciprocal of the r value. Increasing the moisture in the wood also increases its thermal conductivity.

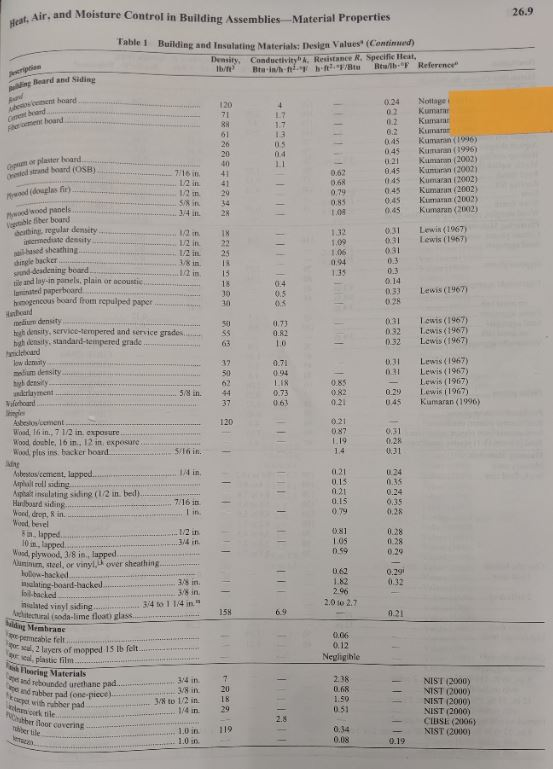

A thermal conductivity of 0 1213 w mk for pine was the product of the hfm measurement. C is known only when the k the thermal conductivity of a material is known. Design values of thermal conductivity at that temperature are presented for all of the common classes and kinds of insulation board hardboard and particleboard. Very high thermal conductivity measurements up to 22 600 w m 1 k 1 were reported by fenton e w rogers j s.

In the direction of the grain the thermal conductivity of wood is about twice what it is perpendicular to the grain. Therefore century trim has a high insulation property which contributes to low shrinkage in use and resistance to fire. In simple terms r values measure the effectiveness of insulation and a higher number represents more effective insulation. Century trim is easy to handle plane sand saw rip route and carve.

Thermal conductivity is a material property that describes ability to conduct heat thermal conductivity can be defined as the quantity of heat transmitted through a unit thickness of a material in a direction normal to a surface of unit area due to a unit temperature gradient under steady state conditions. A collaborative platform that significantly improves the process to chronicle share and advance projects online. This change in construction material can be attributed to the thermal conductivity of softwoods being approximately 1 7 that of brick. For example the thermal conductivity of pine in the direction of the grain is 0 22 w moc and perpendicular to the grain 0 14 w moc.

The coefficient of thermal expansion for panel thickness is approximately 16 x 10 6 inch inch per degree f. In some journal of physics which has its name blurred up in reference 570 on page 1458 41 2026 33 1963.