Thermal Lamination Problems

The laminators have scotch printed on the front.

Thermal lamination problems. Turn the rolls of film supply rolls in the unwind direction. The model number tl901c is printed on a sticker on the bottom of the laminator. The same principles apply to cold laminates. If you don t manage the contact point well air bubbles will get trapped in the middle.

Lamination is all about getting two materials to bond together. Increase the laminating speed just as high speed is bad low speed is also bad as it can cause the pouch to heat up. This will promote a better adhesive flow. Sometimes you may need to do both.

1 1 the film will wrinkle if there is not enough supply roll tension. Use the right temperature check the pouch s specifications on temperature. Another lamination process uses a lamination press after materials are combined in a thicker structure than film. If there aren t any recommendations on.

The heat of the laminating machine as it applies the film can cause wet sheets and inks to bubble and begin gassing resulting in air being trapped between the laminate and the printed sheets. For laminators that have adjustable temperature settings simply increase the temperature in small increments until the cloudiness disappears. They measure 14 inches by 3 8 inches by 2 75 inches. Here are some solutions.

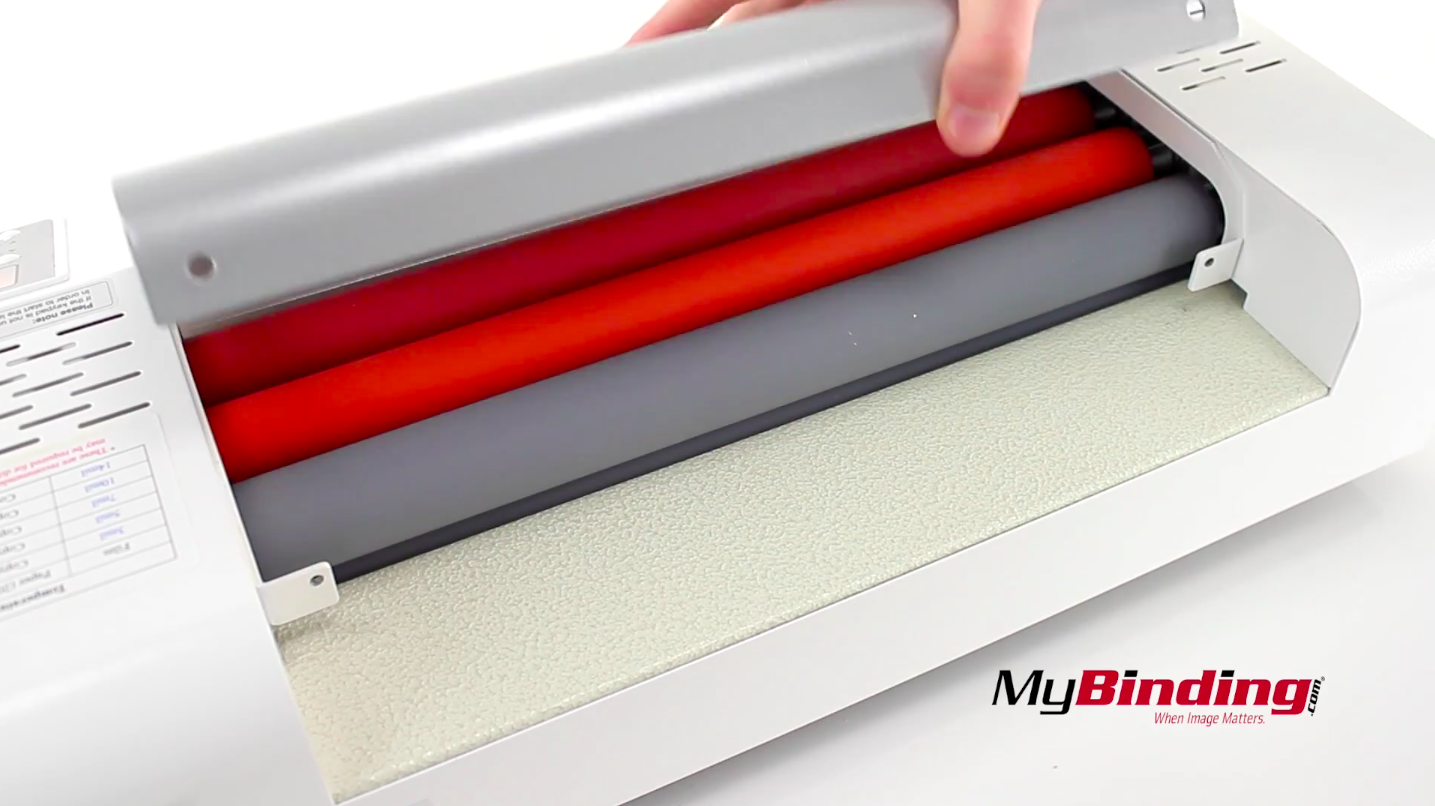

Any laminator needs a certain amount of resistance to the unwinding of the supply rolls so that the film lays flat as it goes into the nip of the laminating rollers. They are used to laminate documents such as artwork and photos. Is there some resistance. The biggest pitfalls for laminators has been the same one that has dogged converters since the dawn of well lamination.

Having the right set up right from the start. With water based or solvent based ink systems uncured inks can create several challenges when the sheet is being laminated with a thermal laminating process. Silvering is caused when the adhesive not wetting out properly this problem is solved by either increasing the temperature setting or slowing down the speed setting.