Thermal Paste Conductivity Calculation

Convective heat transfer heat transfer between a solid and a moving fluid is called.

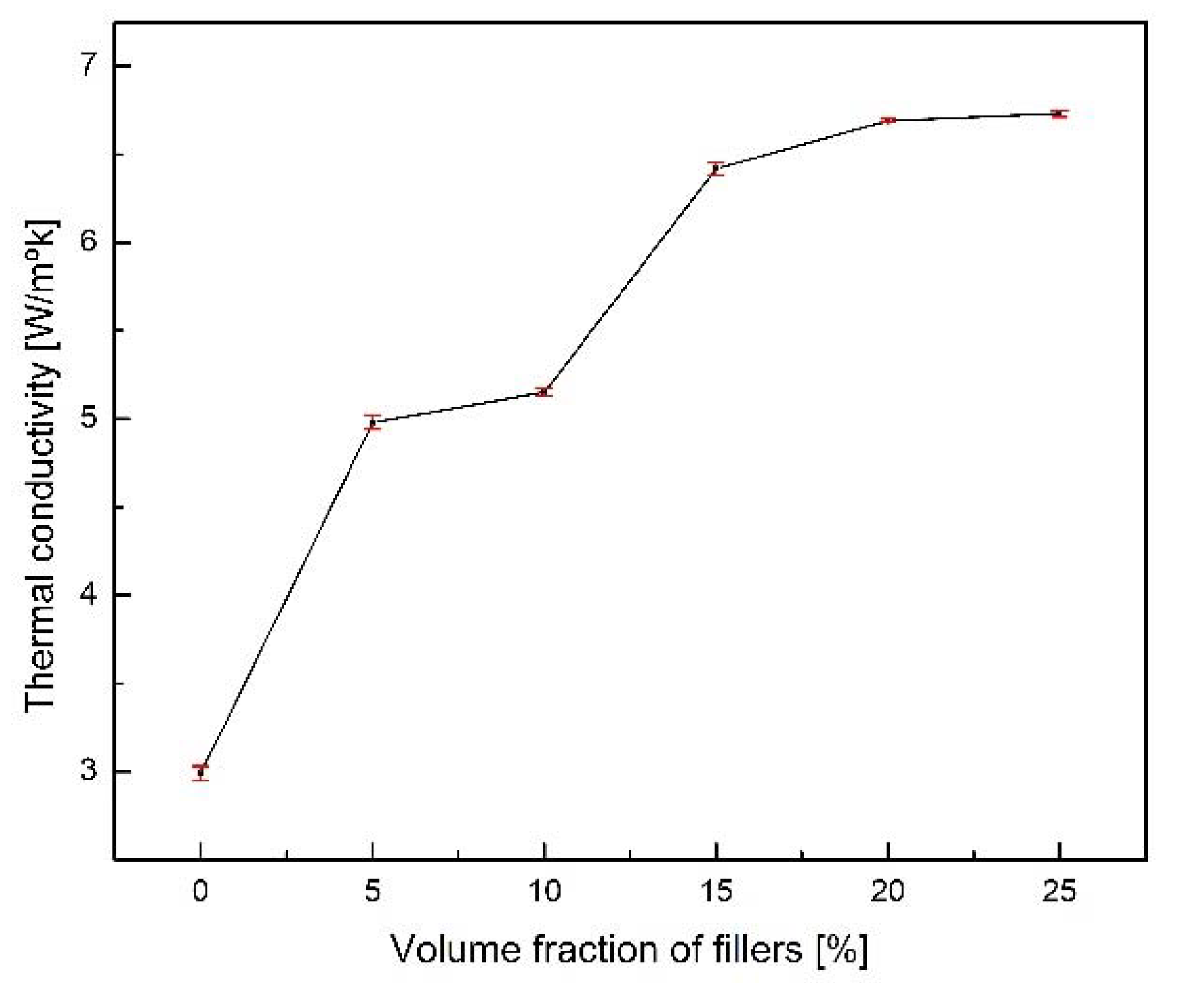

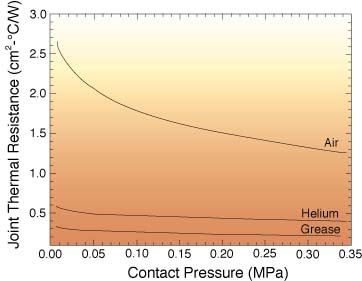

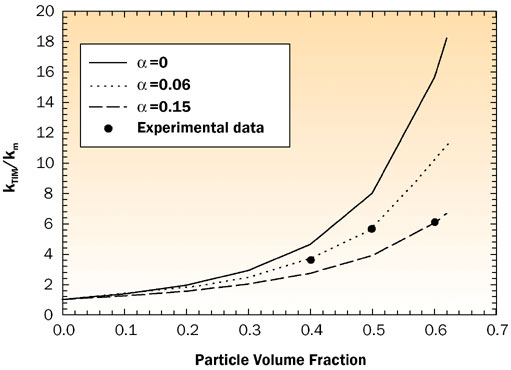

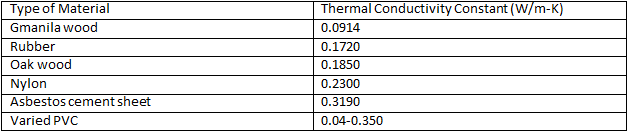

Thermal paste conductivity calculation. Carbon dioxide thermal conductivity online calculator figures and table showing thermal conductivity of carbon dioxide co 2 at temperatures ranging from 50 to 775 c 50 to 1400 f at atmospheric and higher pressure imperial and si units. I found in the manufacturers datasheet is has a thermal conductivity of 1 6w mk watt meter kelvin. Whilst all other data i have for the heatsink is in c w. I m trying to calculate the thermal paste joint between my pcb and the heatsink.

Or select a value from our material database. Price is normally set based upon thermal conductivity and the amount of compound in the tube generally in the range of 3g which is a few uses. This tool generates a quick estimate of the expected junction temperature based on the copper spreading area on the pcb. I my case area is 0 01m 0 009m 0 0000054 sq m k is 1 7 and i have no clue what thickness will be.

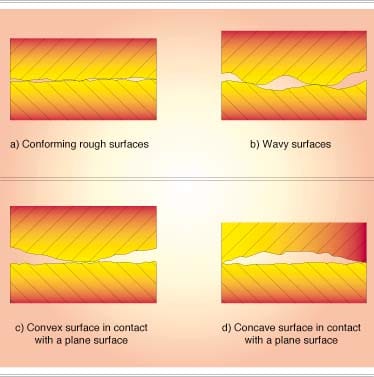

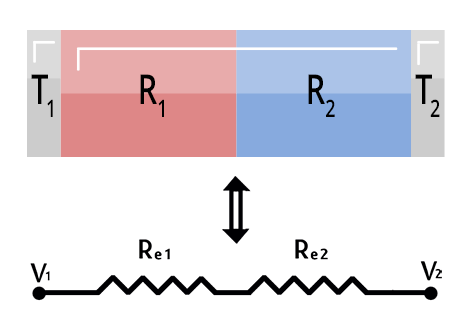

So rglue thickness area k k thermal conductivity. Thermal paste also called thermal compound thermal grease thermal interface material tim thermal gel heat paste heat sink compound heat sink paste or cpu grease is a thermally conductive but usually electrically insulating chemical compound which is commonly used as an interface between heat sinks and heat sources such as high power semiconductor devices. You can see that the thermal compound is actually a poor heat conductor and that is exactly the reason why you only need a very thin layer of paste to fill the micro imperfections between. Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal conductivity.

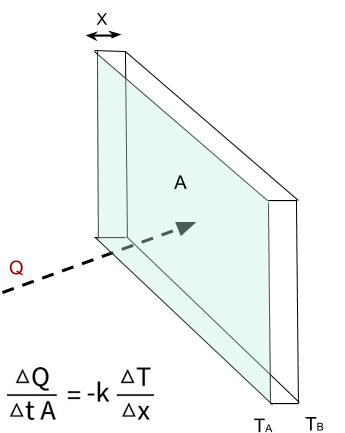

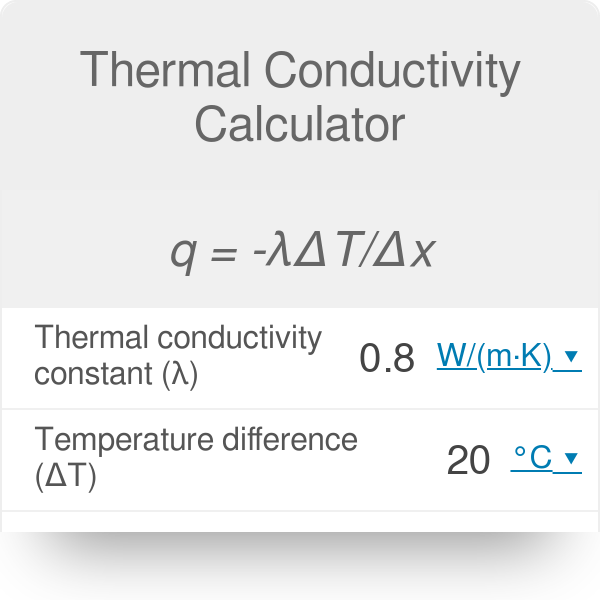

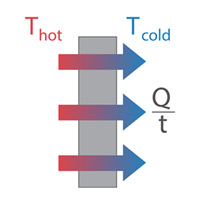

A tube of 8 5w mk carbon based compound which is. But heat sink will be glued using thermal glue like hc910 which has thermal conductivity of 1 7 w m k. How does the heat transfer conduction calculator works. Input the cross sectional area m 2 add your materials thickness m enter the hot side temperature c enter the cold side temperature c.

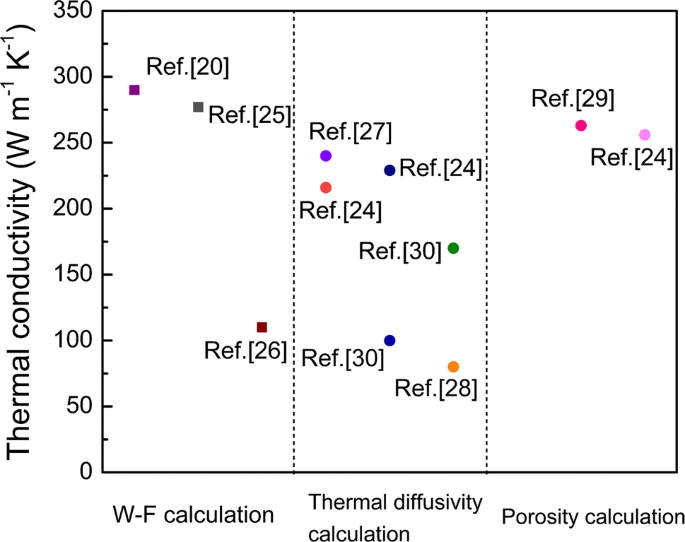

The parameters used to calculate thermal conductivity are the steady state temperatures the heat used for the warmer plate and the thickness of the material. The heat transfer conduction calculator below is simple to use. The pcb thermal calculator helps you estimate the junction temperatures of components which use exposed pad packages. It is very accurate but takes a significant amount of time to.

Enter the thermal conductivity of your material w m k. The thermal conductivity of a material is a measure of its ability to conduct heat it is commonly denoted by or. I took 0 1mm as a wild guess.

.png)