Thermal Printer Ribbon Wrinkle

Another item you can check is the spindle tension.

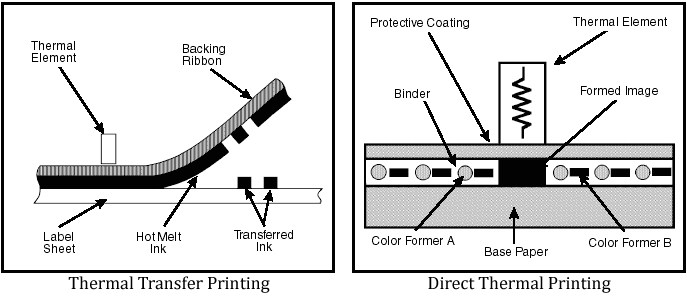

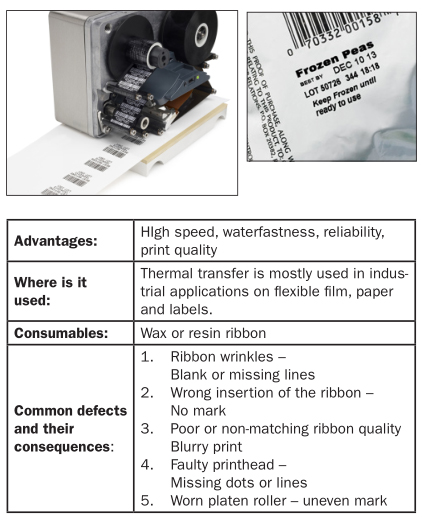

Thermal printer ribbon wrinkle. One of the challenges for thermal printer designers is managing the ribbon within the print system. Ink is scratching off the label as it is fed through the printer. How to fix ribbon wrinkle thermal label printer duration. This kind of uneven printing can cause stress on a ribbon and the ribbon will wrinkle.

While this problem is common on all thermal transfer printers it is most prevalent on the wider web printers since there is more surface area of ribbon moving across the printhead. This can be a serious issue for applications that use bar codes. If barcodes are printing the wrinkle in the thermal transfer ribbon can cause the barcode to be unreadable. When the base film breaks away from the label the ink will cause stress on the base film.

Making that adjustment will even out the pressure all the way across the printhead and hopefully prevent ribbon wrinkle. This effect commonly known as ribbon wrinkle results in streaks or voids on the printed image. Due to the very thin substrate ribbons are vulnerable to puckering and folding. We receive and see posts about zebra printer ribbon wrinkling on zebra z 170xi series and z 220xi series printers.

Below are the most common causes of ribbon wrinkle on any thermal printer by wrinkle it is meant as voids appearing on the printed label. One common misconception about the thermal printers is that the ribbon take up spindle is what pulls the ribbon through the printer but that is not what happens.