Thick Film Ceramic Substrates

Mpt is a one stop shop for your thick film substrate needs.

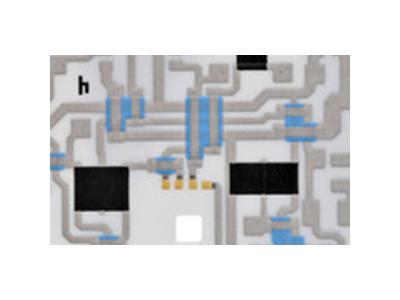

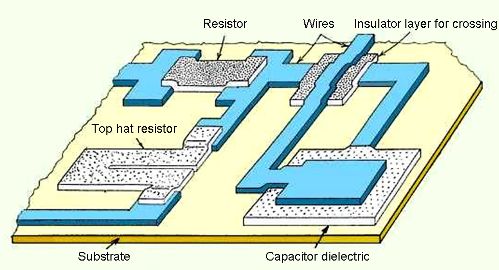

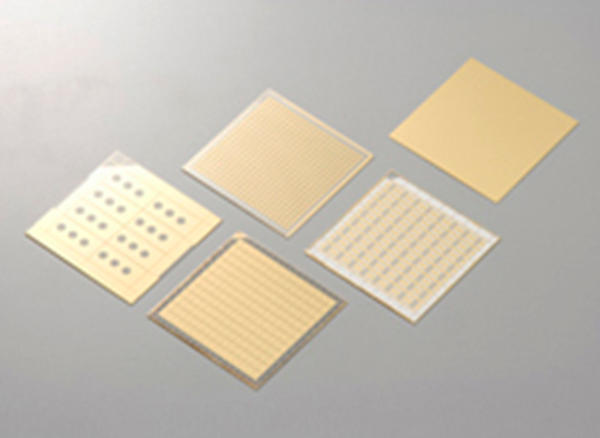

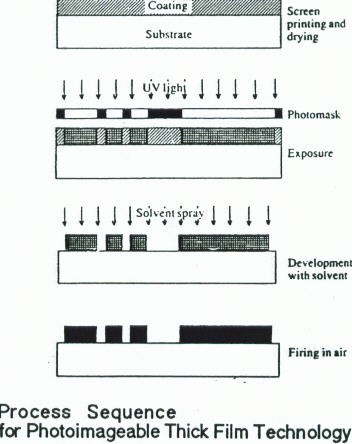

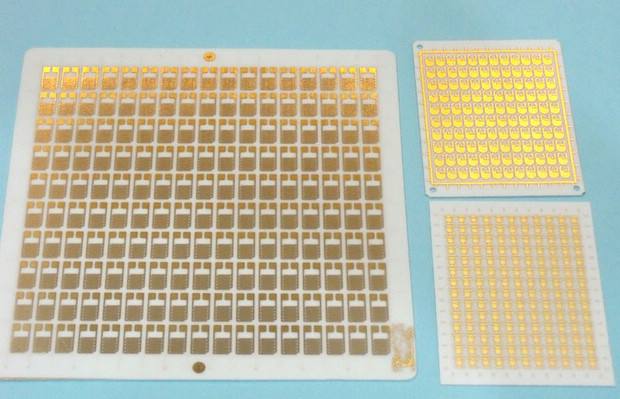

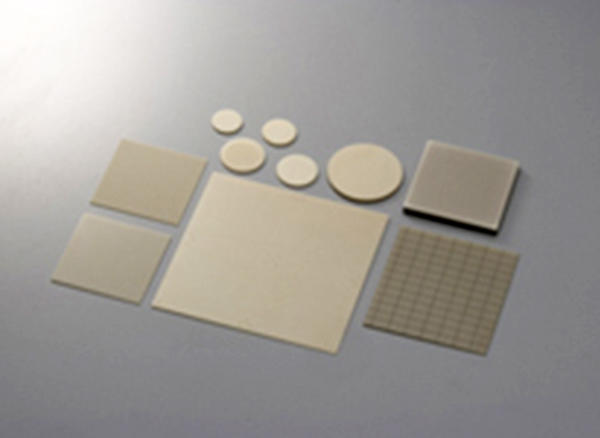

Thick film ceramic substrates. Used in the fabrication of chip and wire hybrid circuits leadless chip carrier motherboards sensor elements assemblies etc. Thick film materials normally require heat treatment in the region of 850 c to form a glassy bond with the ceramic substrate. Thin film circuits are prepared by vacuum deposition usually evaporation or sputtering of relatively thin layers of metals or compounds onto ceramic substrates. Kyocera produces alumina substrates with excellent thick film reliability tightly controlled dimensions no more than 0 25 and small through holes as small as 0 2mm which enable greater density and precision in thick film circuits.

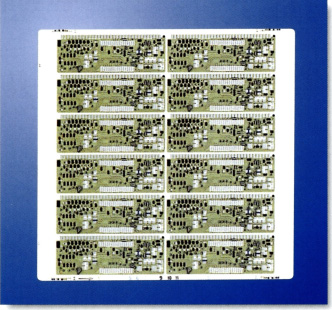

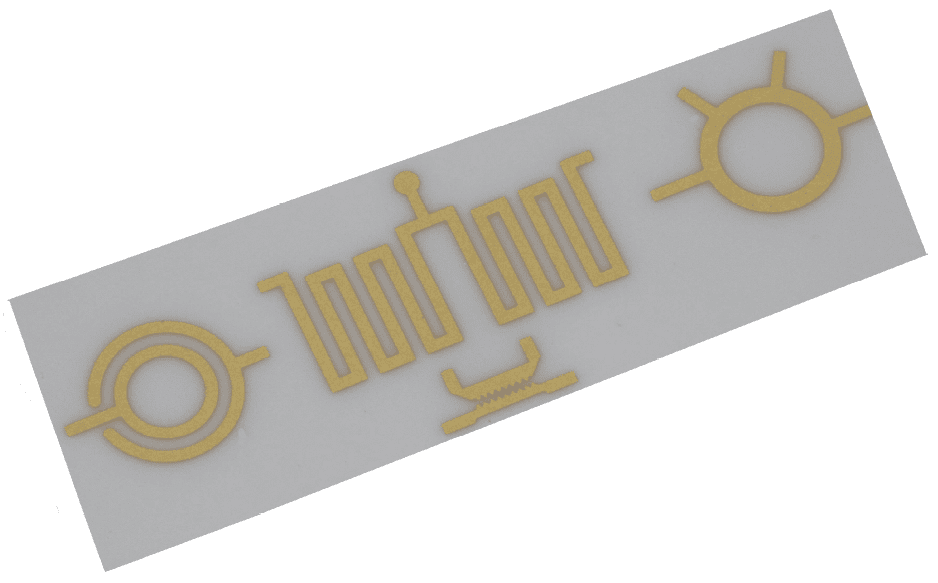

Thick film substrates kyocera s thick film substrates correspond to the increased density and precision of thick film circuits. Mpt thick film technology is robust economical and can reduce the footprint of your circuit. The facility is iso 9001 2008 certified for the design production and testing of thick film resistors thick film chip attenuators thick film ceramic substrates and surface mount assemblies and ltcc. Cms circuit solutions is a producer of sophisticated custom thick film ceramic printed and etched substrates.

Thick film substrates are electronic circuit boards generally made from ceramics. Coorstek has engineered different grades formulations and thicknesses to provide an optimal fit for a variety of. Ceramic fine etched thick film manufactures. Typically thick film circuit substrates are al 2 o 3 alumina beryllium oxide beo aluminum nitride aln stainless steel sometimes even some polymers and in rare cases even silicon si coated with silicon dioxide sio 2 most used substrates for a thick film process are either 94 or 96.

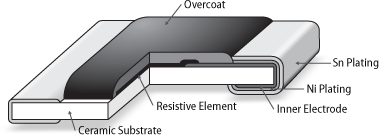

Our on site vertically integrated functions include. The ceramic is screened with conductor insulator and resistor material to form the circuitry. Superior resistor stability is achieved by controlling increase in strength over the standard ads 96r. Ads 96r thick film substrates are engineered to minimize adsr 96r thick film durastrate substrates are a as fired resistor variations and maximize aged adhesion fine grained material which offers greater than a 20 values.

A typical thick film process would consist of the following stages. Why ceramic thick film substrates. Remtec uses pctf and other advanced technologies to design and produce cost effective custom and semi custom packaging solutions metallized substrates packages and components for power electronics optoelectronics and rf mw applications in commercial industrial and military industries. Alumina is the material of choice for most thick film ceramic substrates delivering durable cost effective performance for hybrid electronic circuits with proven reliability.