Thornel Mat Vma

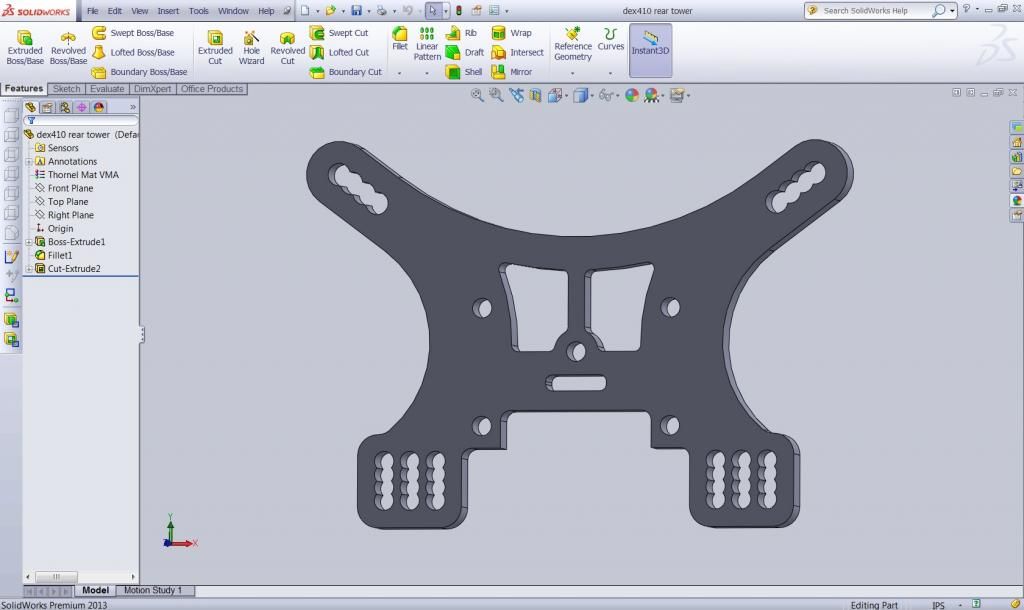

Has completed and tested the first prototype a lower pipe of the front suspension of motorbikes.

Thornel mat vma. Discontinuous fiber tensile strength. 26 5 years of experience thornel s trained and competent sales staff will recommend the optimal system for the project. This is 75 lighter wear resistant and as strong as the original steel one. A process for producing a lightweight electrode grid by exposing a heated t of dense graphite fibers to ni co 4 gas wherein the ni co 4 decomposes upon contact with the graphite fibers depositing.

20 138 average filament. With each step of the process trust the thornel team to systematically manage the project from consultation to custom design and installation. With each step of the process trust the thornel team to systematically manage the project from consultation to custom design and installation. 26 5 years of experience thornel s trained and competent sales staff will recommend the optimal system for the project.

Current situation ceracarbon b v. The thornel portfolio includes a range of performance grades and tow sizes sold in continuous chopped mat and woven form. This page has links to all data sheets in matweb for the tradename thornel. Composed of high strength high modulus carbon filaments in a random layered orientation.

The fine diameter filaments are up to three inches long and are mechanically bonded to form. The thornel line continued with increasingly higher levels of modulus for more than ten years. 175 1 21 tensile modulus. Frequently asked questions.

Solvay thornel mat vma carbon fiber discontinued categories. We have several search tools listed above that give you more efficient methods to reach the information that you need. New deals on 3k 6k and 12k carbon fabrics updated. Discover how we work.

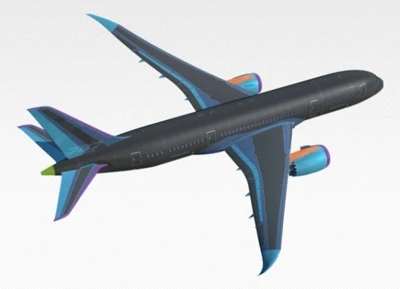

Air force materials laboratory supported much of union carbide s research into rayon based fibers during this period in an attempt to develop a new generation of stiff high strength composites for rocket nozzles missile nose tips and. Thornel pan and pitch based carbon fibers have a long history of use in both aerospace and industrial markets providing exceptional performance for advanced composite applications. Discover how we work.